The calcium carbonate is a key filler for improving the performance and aesthetics of plasters, renders and mortars, while optimizing production costs.

Whether it’s for fillers, joint finishes, adhesive mortars, facade coatings or plasters, the choice of calcium carbonate is crucial and must be studied according to the desired characteristics.

The geographical coverage of our production sites reduces supply distances.

Benefits

Whiteness and surface appearance

Calcium carbonate is one of the whitest fillers, giving plasters high levels of whiteness. The surface appearance of the plaster is also controlled by the grain size of the calcium carbonate used.

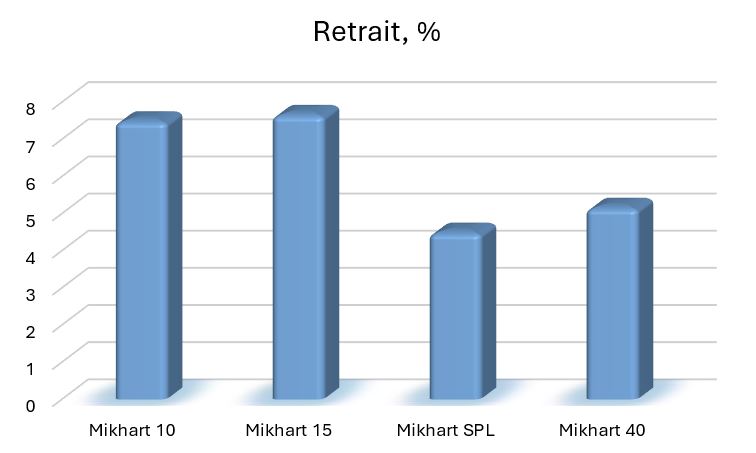

Shrinkage and water retention control

The use of calcium carbonates with a suitable particle size distribution helps to control water retention and minimize plaster shrinkage during drying, which is particularly important for filling plasters.

Garnishing

The plaster's filling effect is achieved by the appropriate choice of calcium carbonate, which increases the plaster's ability to fill irregularities and ensures even application.

Easy to apply

The ease with which plasters can be applied also largely depends on the choice of calcium carbonate. In particular, it controls slipperiness, a very important feature for finishing plasters.

Texture control

Calcium carbonate can be used to modulate the structure of finished products, whether smooth or granular. The use of small grains of calcium carbonate thus makes it possible to obtain the desired finish in single-coat plasters.

Cost reduction

Calcium carbonate is the filler of choice for optimizing the cost of plasters of all types.

Fillers

Fillers

Filler coatings

Filler coatings

Finishing / smoothing plasters

Finishing / smoothing plasters

Joint fillers

Joint fillers

Adhesive mortars

Adhesive mortars

Single-coat rendering, rendering, ITE systems

Effect of different CaCO3 on shrinkage in a filler-type plaster formula :

For these applications, we also offer glass beadsbeads pigment preparationspreparations biocides, antifoams and dispersantsdispersants cellulose fibers and wood flourwood flour barium sulfatetalc talctalc micaand kaolinand feldsparsynthetic synthetic corundumsynthetic anhydritetitanium titanium dioxidetitanium dioxide zeolitezeolite alumina trihydrate and amorphous silica.

283, Avenue Frédéric Mistral

CS 40097

83175 Brignoles cedex

Tel. +33 4 94 72 83 00

The company

Stay connected!

2025 All rights reserved