The calcium carbonate is the mineral filler of choice for adhesives and sealants. It enables formulations to reduce their carbon footprint and optimize costs, while improving mechanical properties and controlling rheological properties.

Benefits

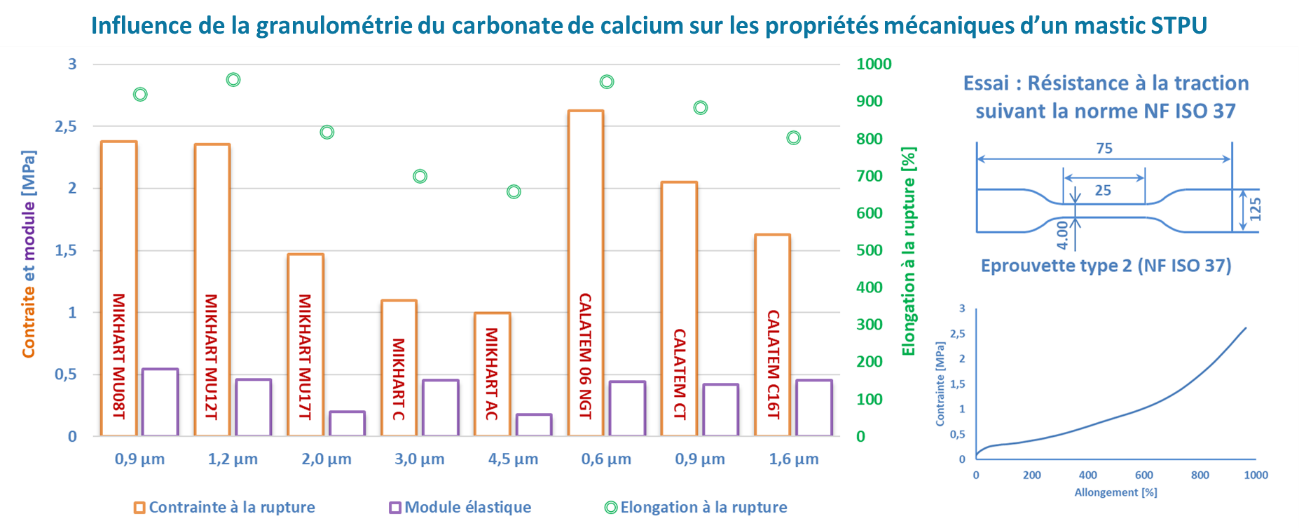

Improved mechanical properties

Calcium carbonate acts as a filler, influencing both the cohesion and adhesion of an adhesive. It reinforces the adhesive's internal structure, increasing its mechanical strength and durability, while modifying the interaction between adhesive and substrate to promote better adhesion.

Optimized rheological properties

The use of calcium carbonate greatly influences the rheology of an adhesive or sealant. It therefore controls the way the adhesive spreads, adheres and resists mechanical stress during application (creep resistance). The right choice of calcium carbonate helps to limit sedimentation and thus increase pot life.

Improved service life and VOC reduction

Thanks to an optimized surface treatment, the water content of calcium carbonate is minimized, reducing the amount of moisture fixative in the formula. The use of these calcium carbonate grades therefore helps to extend the life of reactive systems at lower cost, while reducing VOCs.

Lower formula costs

Calcium carbonate is a cost-effective solution for reducing the overall cost of the adhesive or sealant formula while maintaining high performance.

Modification of surface appearance

Naturally white, calcium carbonate will increase the whiteness and opacity of the final product. It will also influence the tactile texture of the adhesive or putty after drying, depending on the particle size of the calcium carbonate used.

Reducing environmental impact

Calcium carbonate is a natural, inert and non-toxic material. Environmentally-friendly, it helps reduce carbon footprints by cutting down on the use of petroleum-derived materials.

Provençale SA offers a wide range of solutions specifically developed to meet the requirements of reactive systems. These products feature a narrow particle size distribution to achieve ever higher loading rates, and are surface-treated to minimize water content and improve affinity with the adhesive matrix for optimum dispersion. The use of these products makes it possible to achieve excellent mechanical performance and control formulation viscosity, while optimizing production costs and reducing environmental impact. The use of these calcium carbonates is particularly recommended for the formulation of :

- Hybrid polymers / STP (Parquet)

- Polyurethane adhesives

- Silicone

- Polysulfide

As with reactive systems, Provençale SA offers a wide range of solutions for non-reactive systems. Calcium carbonates improve the mechanical properties, whiteness and opacity of adhesives and sealants. The use of calcium carbonates is particularly recommended for the formulation of :

- Pressure-sensitive adhesive tape

- Acrylic sealants

- Tile adhesives

- Solvent-based systems

- Hot-melt adhesive

- Paper and packaging glue (aqueous)

For these applications, we also offer glass beadsbeads cellulose fibers and wood flourand pigment preparationsbiocides biocides, defoamers and dispersantsdispersants micaand kaolinand titanium dioxideand wollastonitewollastonite tri-alumina hydrate and amorphous silica.

283, Avenue Frédéric Mistral

CS 40097

83175 Brignoles cedex

Tel. +33 4 94 72 83 00

The company

Stay connected!

2025 All rights reserved