The calcium carbonate is the most widely used mineral filler in polymers. Its surface treatment ensures excellent affinity with polymer matrices, facilitating dispersion during processing. It improves the mechanical, thermal, optical and environmental properties of finished products, while reducing costs.

Benefits

Improved mechanical properties

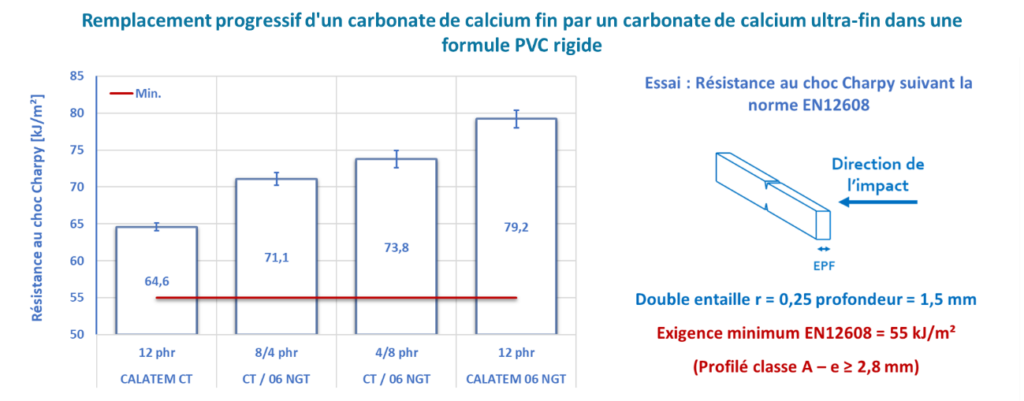

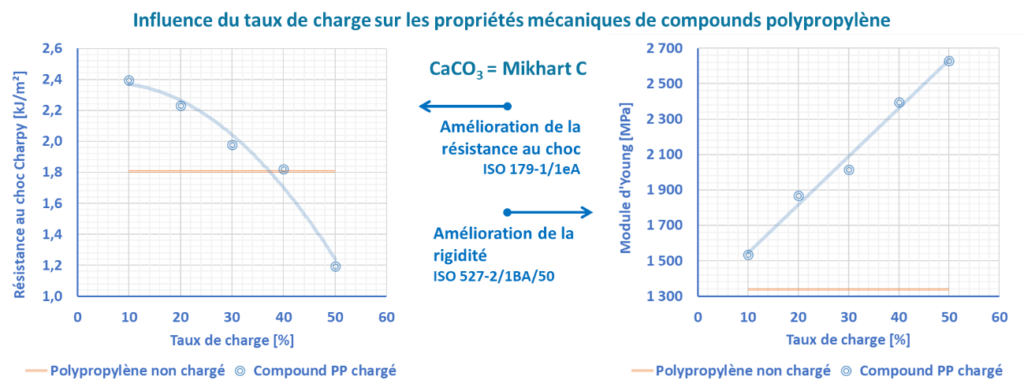

The use of calcium carbonate improves the stiffness and hardness of the polymer matrix (increasing tensile and flexural modulus). It will also have an effect on the polymer's dimensional stability by reducing shrinkage during the cooling stage. Finally, in the case of PVC and polypropylene, certain surface-treated calcium carbonates can improve the matrix's impact resistance.

Optimized rheological properties

The use of calcium carbonate enables the rheology of the filled matrix to be adjusted. Special grades of calcium carbonate limit the increase in viscosity at high filler contents.

Improved thermal stability

Calcium carbonate plays a key role in the thermal stability of PVC, acting as an acid scavenger to limit matrix degradation during processing (secondary stabilization).

Improved thermal conductivity

In the field of polyolefins, calcium carbonate improves the thermal conductivity of the filled matrix, thus reducing injection cycle times and increasing extrusion production rates.

Modification of surface appearance

Calcium carbonate can be used to modify the surface finish of a finished product, reducing its gloss or rendering it matt. CaCO3 particle size also plays a role in product roughness. Larger particles give a rougher or textured appearance to the surface, while finer particles contribute to a smoother surface. Lastly, calcium carbonate's natural whiteness enhances the whiteness of the finished product and adds opacity.

Reducing environmental impact

Calcium carbonate is a natural, chemically inert (except in acidic environments) and non-toxic material. Environmentally-friendly, it helps reduce carbon footprints by cutting down on the use of petroleum-derived materials.

Increased recycled content

Certain calcium carbonates are considered as recycled materials within the meaning of ISO 14021 and can therefore contribute to increasing the recycled content of finished products.

Plastics (PVC) for construction

Masterbatches and compounds

Rubber and elastomers

Thermoset composites (SMC-BMC)

Engineering plastics

Plastisols

For these applications, we also offer glass beadsbeads cellulose fibers and wood flourand pigment preparationspigment preparations titanium dioxidetitanium dioxide barium sulfatebarium sulfate micaand feldsparand amorphous silicaamorphous silicaanhydriteanhydrite wollastonite and alumina trihydrate.

283, Avenue Frédéric Mistral

CS 40097

83175 Brignoles cedex

Tel. +33 4 94 72 83 00

The company

Stay connected!

2025 All rights reserved